Heat pump experts from all over the world will once again gather in Nuremberg

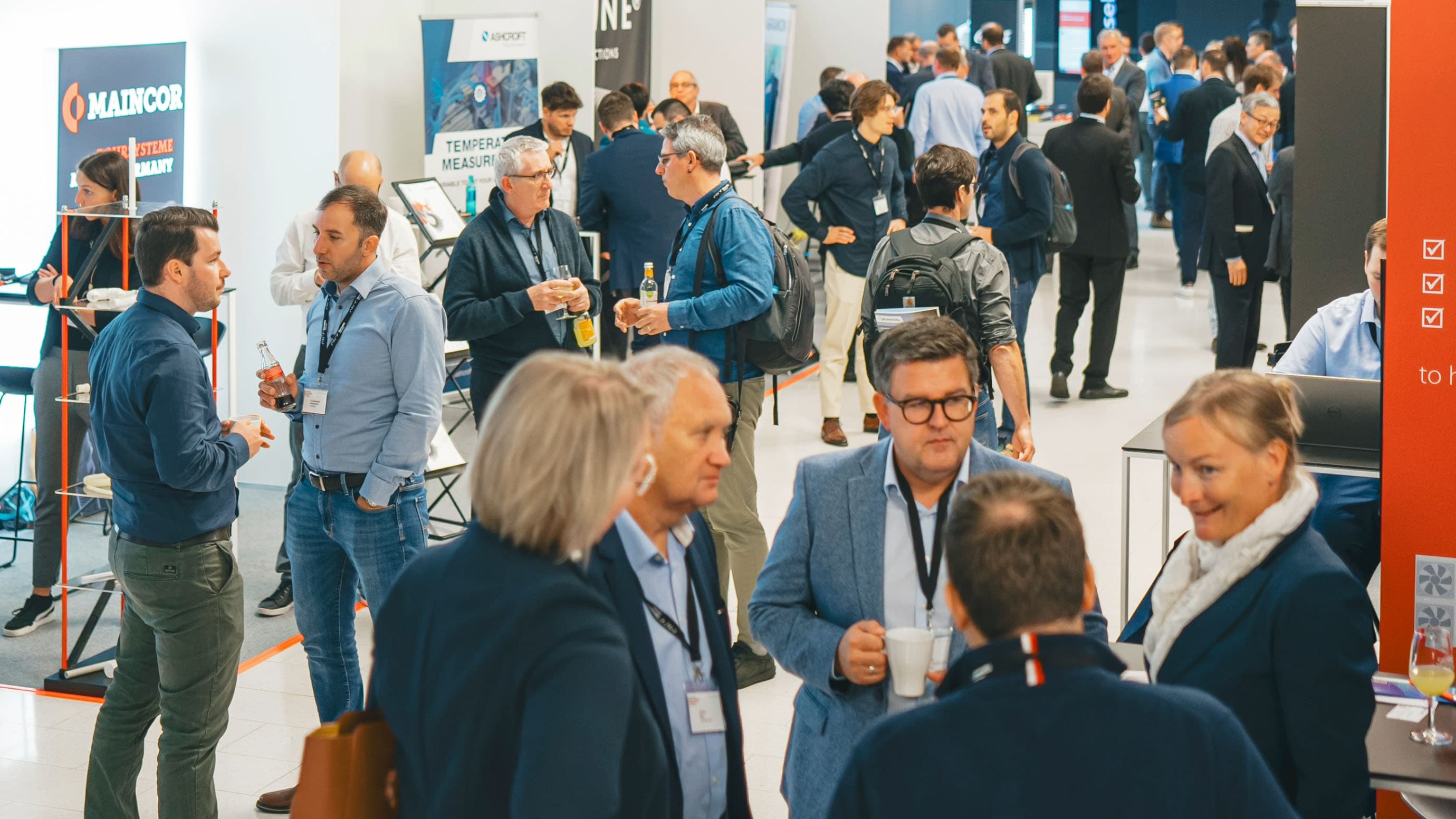

Prestigious speakers will meet international decision-makers from industry, trade and science. Current market developments, topics from research and development as well as trends in application will be discussed.

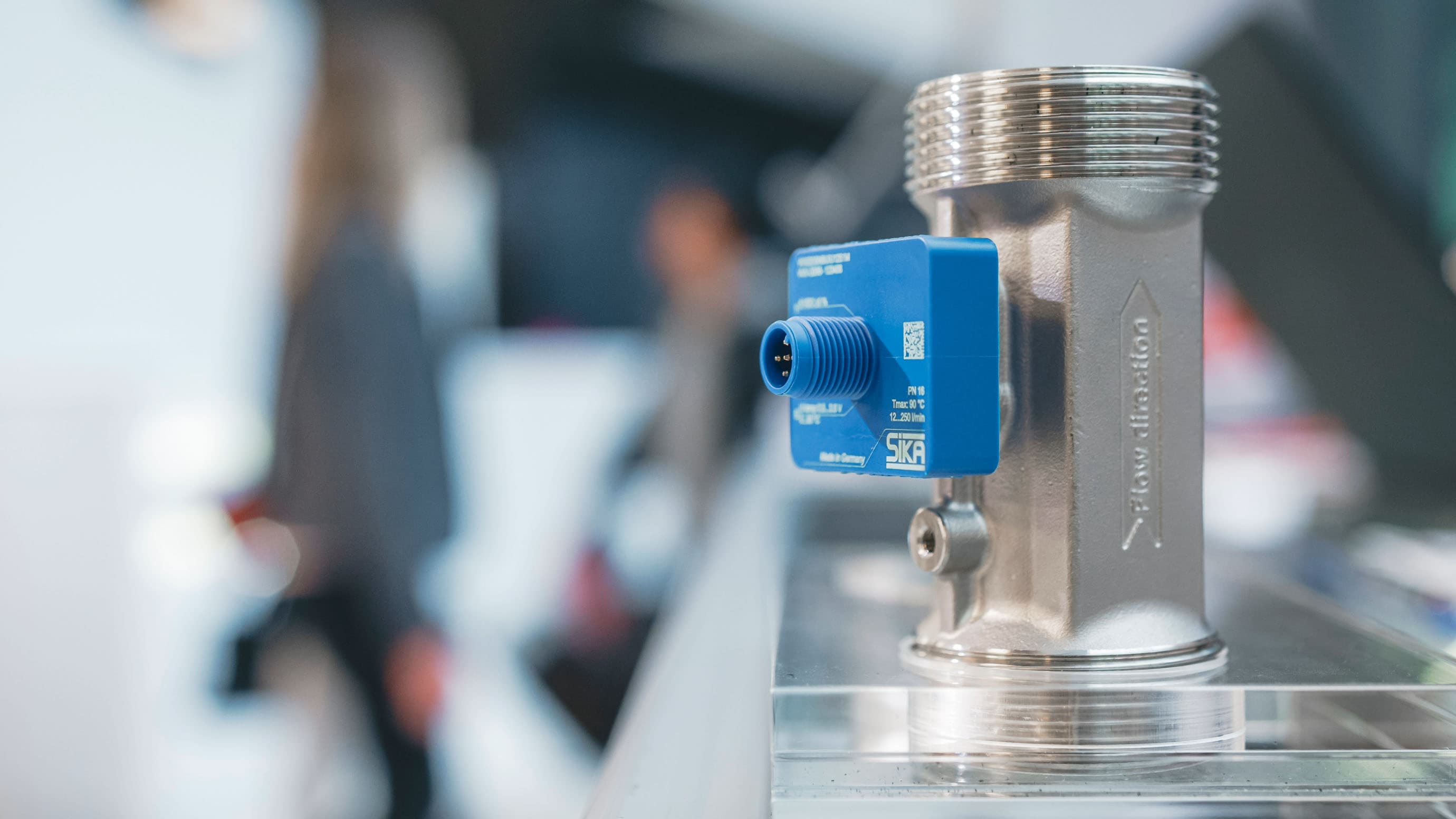

The accompanying Foyer Expo complements the European Heat Pump Summit by providing a platform for companies and professional associations to introduce their services and product innovations to top-level industry visitors. Take this opportunity to engage directly with summit participants and engage in professional dialogue at a high level!